By 2026, experts predict that the supply chain industry in the US alone will reach a total value of $31 billion. With billions of dollars continuously passing through this sector, supply chain leaders are continuously looking for potential methods of streamlining processes and optimising profit.

With the rise of generative artificial intelligence (AI), all eyes are on how this technology can shape, restructure, and increase the efficiency of the supply chain industry. Business leaders are increasingly turning to AI solutions, with 80% of CEOs planning on deploying AI technology over the next two years.

Yet, for many supply chain CEOs, AI isn’t a new solution. Over 98% of executives state that AI has been fundamental in revolutionising at least one aspect of their supply chain operations. With the potential to streamline logistics, enhance the accuracy and speed of forecasting, and provide real-time risk and inventory management capabilities, AI is becoming a major player in this space.

In this article, we demystify the presence and influence of generative AI in this sector, outlining the CEO’s vision to incorporate AI into current and predicted use cases. We’ll detail how supply chain companies can use generative AI, as well as trace the long-term impact it will have on supply chain operations.

Navigating the Complex Supply Chain Landscape

With advances in globalisation, product and service diversification, and increasing demand for personalisation, the modern supply chain has become increasingly complex.

For enterprises operating in this space, the first step to overcoming these potential challenges is understanding them.

Here are some of the most pressing supply chain complexities:

- Unforeseen Disruption – Supply chain disruptions cost countries around the world an average of around $184 million each year. Whether from extreme weather, energy shortages, geopolitical conflicts, or cyberattacks, unforeseen circumstances add a layer of uncertainty to this industry.

- Variable Risk – With various concurrent processes, supply chain management has to account for a constantly shifting range of risks. Calculating and accounting for variable risk can abstract a fairly simple process into one with intricacies.

- Varying Degrees of Digitisation – Research from McKinsey suggests that only 43% of the average supply chain is digitised. Manual processes create inconsistencies, room for human error, and siloed data.

- Evolving Regulations – Compliance monitoring and regulatory frameworks develop, adjust, and evolve over time. Major compliance shifts involve the re-optimisation of processes that can create delays.

To combat these supply chain challenges, CEOs search for innovative solutions. Increasingly, the leading solution to various aspects of all these issues has been artificial intelligence, with its range of deployment use cases allowing it to navigate these complexities effectively.

Demystifying Generative AI

Generative AI is a subsection of artificial intelligence that excels when engaging with tasks related to innovation, creativity, and the production of content or information. The underlying technology of AI utilises neural networks to process vast datasets rapidly, observing patterns, trends, and relationships within the data.

By leveraging that knowledge, generative AI systems can hone particular skills, several of which offer transformative capabilities for supply chain operations.

Between 2022 and 2032, generative AI in the supply chain market has a predicted CAGR of 45.62%. This increase would surge the total market value of GenAI in this field from $300 million to over $12,941 million.

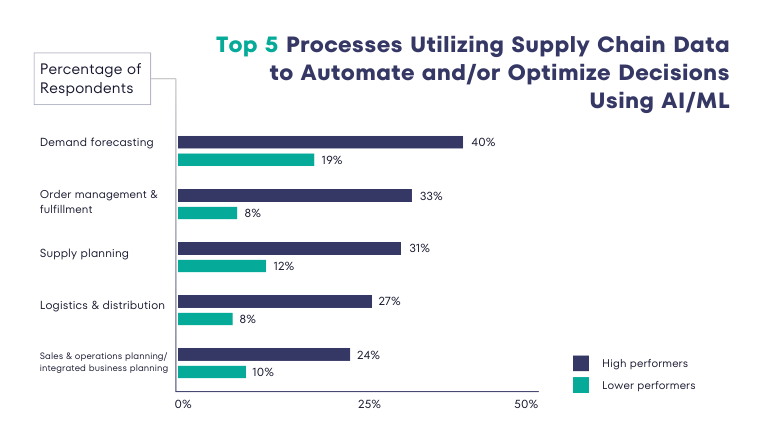

Research suggests that artificial intelligence can streamline numerous aspects of the supply chain, ranging from logistics and supply planning to order management and demand forecasting.

Source: Gartner (February 2024) – Let’s explore some of the leading AI applications in the supply chain industry

Revolutionizing Forecasting Accuracy with AI

Supply chain forecasting helps vendors to predict and monitor potential supply and demand. By analysing data from previous years, companies aim to forecast future figures accurately, aiding them in optimising for future operations.

Forecasting errors, where differences arise in calculations and actual demand or supply, can lead to profit loss, high lead times, and customer churn. Vendors that demand forecasting accuracy to avoid these potential outcomes are readily turning to artificial intelligence.

Machine learning algorithms can actively improve their forecasting accuracy over time. Through an iterative process, these algorithms can hone supply chain AI forecasting simulations, providing a more accurate and effective model. Artificial intelligence in forecasting has improved accuracy by around 23% when combined with human assistance.

Yet, as we are still relatively early in the production of AI technologies, this figure is only the beginning. As AI and ML tools continue to develop, they will become central to the success of forecasting, helping to produce the decision-making insights that allow vendors to thrive in their sector.

Optimizing Inventory Management

Effective inventory management is the heart of the supply chain, with vendors needing complete visibility over shipments, stock levels, and demand forecasts to ensure timely delivery.

However, even in enterprise environments, inventory management issues are more common than one may initially believe. Research suggests that 34% of supply chain businesses have shipped an order late due to selling a product that was not actually in stock.

The vast majority of errors in inventory management come from human error. Whether that’s in mismanagement or misuse of software or written errors that create problems upstream, everything costs businesses money.

Source: Meteor Space

Artificial intelligence, able to perform human-like tasks with 100% accuracy, instantly eliminates the chance of human error. Equally, its automation of manual processes enhances the efficiency of inventory management and streamlines warehouse operations.

Research from McKinsey suggests that AI-driven inventory control can present a cost-saving opportunity of 35%. This optimised inventory management system helps to eradicate errors, improve operations, and eliminate potential data silos that occur in warehouse environments.

Streamlining Logistics with AI Precision

Artificial intelligence has the potential to radically improve route planning and optimisation. By using machine learning algorithms, AI can provide dynamic routing, adjusting logistics pathways in real-time to provide a more efficient route.

AI route optimisation enables businesses to access a level of logistics precision that has previously been impossible. By integrating data about fuel consumption, vehicle capacity, delivery schedules, and transit times, AI algorithms are able to streamline logistics pathways.

Companies that have already incorporated AI into their route planning and logistics processes have seen a 15% increase in cost-savings. Leading logistics and transportation companies like Amazon, UPS, and DHL are already making use of AI-powered route planning to enhance their overall supply chain efficiency and improve last-mile delivery.

Real-Time Risk Intelligence for Proactive Decision-Making

When constructing a resilient and effective supply chain, businesses must consider potential risks their businesses may encounter. By identifying potential risks, a company can then quantify their intensity and importance, taking steps to produce mitigation strategies that maximise cost savings while minimising risk tolerance.

Able to compute vast quantities of data concurrently, artificial intelligence is able to determine the most cost-effective risk mitigation strategies in real-time. This form of real-time risk intelligence constantly adapts to varying factors to suggest the best possible course of action.

Beyond just qualifying risk, an AI-enabled approach to risk intelligence allows for proactive decision-making. One of the leading factors in preventing disaster scenarios from occurring is early mitigation. The efficiency of AI provides businesses with more time to assess, quantify, plan, and implement factors to effectively mitigate risk.

AI-enabled risk intelligence can help streamline this vital endeavour across every stage of the supply chain.

CEO Testimonials: Voice of Innovation

Many leading CEOs in the supply chain space have already taken steps to incorporate artificial intelligence into their business operations. Let’s hear from three supply chain CEOs on how their companies are engaging with AI.

Hilti

To make its supply chain fit for the future, Hilti Corporation, a global player in the construction industry, has revisited its supply chain risk management setup. The result has been a strategic inclusion of tech and trends like AI (Artificial Intelligence) and ML (Machine Learning).

According to Brian Sieben, Global Process Owner for Supply Management at Hilti, the cumulative impact on supply chain risk management has been phenomenal: “As the Global Process Owner for Supply Management at Hilti Corporation, I’ve witnessed the transformative power of Prewave’s AI in our operations. Partnering with Prewave allowed us to replace an outdated proprietary software tool and elevate our risk management to new heights. As a direct sales company in the construction industry, product availability is paramount for us, and Prewave’s consequence-based risk management has been instrumental in ensuring stellar product availability figures. The integration of different information sources, dynamic risk monitoring, and exceptional usability make Prewave invaluable for our supply managers, driving enthusiasm for this outstanding tool.”

Audi

Producing over 1.6 million units worldwide, Audi is one of the leading car manufacturers in the world. Audi uses artificial intelligence to enhance its supply chain, minimise risk, and increase transparency.

Marco Philippi, Head of Procurement Strategy at Audi, comments on this, “The key advantage of AI is the speed at which it can recognise relevant news online and transmit this in bundled form. This enables us to find out about sustainability risks much earlier on, so we can respond more quickly. AI is an ideal example of how digitalisation can contribute to greater transparency in the supply chain.”

This sentiment is echoed by Susanne Lenz, Supply Chain Sustainability Strategist at Audi, “Analysing massive amounts of data using artificial intelligence highlights how digitalisation can uncover risks in our supply chain. Thanks to our collaboration with Prewave, we are using an adaptive, powerful tool to increase transparency and efficiently monitor sustainability agreements.”

UPS

With over 25 million packages to deliver each day, UPS has embraced AI to streamline delivery logistics. UPS is using artificial intelligence to gain complete visibility over its supply chain and helping to expedite delivery with last-mile route planning and optimisation.

Bob Stoffel, former Senior Vice President of Engineering, Strategy, and Supply Chain at UPS, comments on the AI’s capability to improve supply chain visibility, “When we talk about supply chain visibility, it does not simply mean visibility into your own supply chain. It means visibility among partners, which enables collaborative decision-making closer to the customer. This is both a science (managing the technology) and an art (using the information and metrics for competitive advantage).”

Porsche AG

Another giant in the automobile manufacturing industry, Porsche, uses artificial intelligence to enhance sustainability efforts. Research demonstrates that customers are increasingly buying from brands that prioritise sustainability throughout their processes.

Markus Wagner, Head of Procurement Strategy and Sustainability at Porsche AG, suggests that “Prewave enables us to manage risks in a targeted manner – even in the lower-level supply chains. For us, this is about transparency. Artificial intelligence simplifies the complex analysis of data, allowing us to address partners directly and request improvements in sustainability. The goal is to achieve this in partnership with suppliers. In the event of escalation, however, termination of business relations is certainly also an option.”

Gartner

In research aimed at exploring the impact of AI in supply chain management, Gartner reveals a strong correlation between AI adoption and enhanced productivity.

Ken Chadwick, VP Analyst in Gartner’s Supply Chain Practice, comments that “Top performing supply chain organisations make investment decisions with a different lens than their lower-performing peers. Enhancing productivity is the key factor that will drive future success, and the key to unlocking that productivity lies in leveraging intangible assets. We see this divide, especially in the digital domain, where the best organisations are far ahead in optimising their supply chain data with AI/ML applications to unlock value.”

Overcoming Implementation Challenges

As a developing technology, the introduction of AI on a global scale has encountered legal, governmental, and security challenges. In an industry where every second counts, these issues initially cautioned many supply chain businesses from integrating AI.

Here are common AI implementation challenges paired with a solution that can lead to successful integration:

- Regulatory Changes – Although developing due diligence laws have stagnated implementation for many businesses, companies now have enough information to proceed effectively. The EU Risk-Based Regulation and the US 2023 EO on Artificial Intelligence detail integration strategies for AI that abide by future compliance initiatives.

- Data Security – Businesses are increasingly utilising AI that has closed training networks. Training AI on internal data can help reduce security vulnerabilities in data protection.

- AI Hallucinations – AI hallucinations, where generative AI tools produce incorrect information, are becoming increasingly infrequent as businesses implement more stringent human-first fact-checking. Supply chain businesses can use AI-quality assurance checks to decrease the potential for incorrect data to impact operations.

- Limited Worker Knowledge – Organisations around the world are investing more money in AI training for their workers. As employees become familiar with AI tools, they’ll be able to get more from them and continue to streamline the global supply chain.

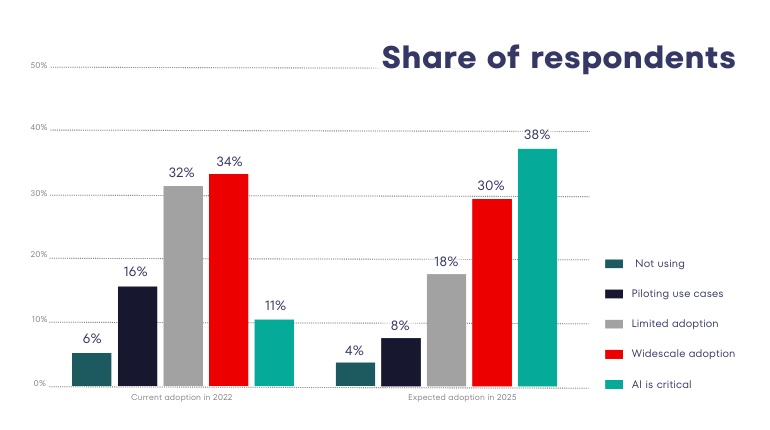

Due to the ability to overcome these AI implementation challenges, implementation rates within supply chain businesses are already on the rise. By 2025, only 4% of businesses will not use AI, with 38% deeming AI-enabled technologies to be mission-critical to their operations.

Source – Artificial intelligence adoption rate in supply chain and manufacturing businesses worldwide in 2022 and 2025.

Navigating Future Trends in Generative AI: A Look Ahead

For supply chain businesses, staying competitive in the age of artificial intelligence means understanding future trends in generative AI and adapting to them ahead of time. While initial integrations will offer enhanced operations and streamlined processes, companies that are able to stay in line with cutting-edge AI research will see the largest growth potential from this technology.

Here are a selection of future trends in generative AI that are garnering attention:

- Enhanced Personalisation – As generative AI continues to develop, businesses will be able to serve customers and clients with a higher degree of customisation and personalisation in the supply chain. AI will reduce the resources needed to deliver these tailored experiences, improving customer satisfaction.

- End-To-End Visibility – An increase in artificial intelligence tools will help defeat data silos across the supply chain, providing full end-to-end visibility and reducing data inconsistencies.

- Natural Language Processing for Customer Services – To ensure the best possible experience, supply chain businesses need to manage client and customer communication. As NLP continues to advance, we’ll likely see automated chatbots and AI-assisted agents rise to the Top of customer service.

As new capabilities of generative AI emerge, they present further opportunities for supply chain innovations. Dr. Ilya Jackson, a Postdoctoral Associate at MIT, suggests that the next 10 years could completely transform supply chains as we know them, “Supply chains could be highly autonomous, with AI-driven systems managing much of the processes, from procurement to delivery.”

CEOs should attempt to closely follow developments in the AI field. The rapid induction of new technologies and capabilities can lead to a competitive advantage that pushes your company ahead of the curve.

Final Thoughts: Shaping the Future of Supply Chain Operations

Generative artificial intelligence has the potential to radically enhance supply chain operations on a global scale. From data-first innovations that improve order and inventory management to risk-analysis and prediction, AI will serve as a vital part of the supply chain of tomorrow.

Yet, as these technologies become increasingly available, the companies that thrive will be those with CEOs that are ready to adapt to these changes. CEOs with a concrete vision of future innovation will help shape the future of supply chain operations and push toward peak efficiency.

About Prewave

Pioneering a breakthrough era for supply chain management, Prewave has become synonymous with transparency, resilience, and sustainability. At Prewave, we harness the power of publicly accessible information from local news, social media, and other databases to fully understand and report potential risks affecting suppliers and commodities across all supply chain tiers.

Leveraging a sophisticated AI algorithm, Prewave efficiently analyses content in over 100 languages across more than 150 risk categories, ensuring that no supply chain disruption remains undetected. This innovative approach has positioned Prewave as an indispensable ally in fostering a more sustainable and resilient global supply chain ecosystem.

To learn more about how Prewave can help you drive change, book a demo today!